Make sure the width of the lines is at least 1 mil or larger. The board is milled/cut to the middle of the line, so thickness of the line does not impact the result. Making the thickness of the lines a non zero number will reduce problems down the road with external gerber viewers. Drawing Cut Outs and Slots. The definition of plated slot. For a board, it may contain plated slot or unplated slot. Plated slot means this slot is plated with copper which can be used for electrical connection. Pictures to show. Size of plated slot. The min side of plated slot is 0.5mm for PCBWay. For unplated slot, the min size is 0.8mm width.

.jpg)

Altium Board Slots Free

The footprint on the left in this image clearly leaves much more empty space around the component leads, where the image on the right provides a snug fit. This makes the circular hole configuration much more prone to common PCB Assembly defects such as solder joint voiding, since more solder is required to fill the holes.These concerns become more significant as the size of the pins increases, from both design and production perspectives, so large blade-style connectors should definitely use plated slots rather than circular holes. At Bittele, we can still work with circular holes for rectangular pins when the part is relatively small, such as the standard barrel power connector used in this example. That being said, the circular holes do also take up more space on the PCB itself, and using plated slots can often help in size-restricted designs.

For the design of non-circular holes, a few things must be considered, but the process is fairly straightforward overall. It should first be noted that slots can be defined as plated through holes (PTH) or non-plated through-holes (NPTH). PTH slots are most often used in component footprints, and most PCB layout CAD programs provide an option in their footprint editor to define a hole as circular or oval. This will be enough for Bittele's PCB Fabrication team to recognize the hole and use the correct process, but for extra clarity, some clients also indicate slot holes on a fabrication layer of their Gerber files.

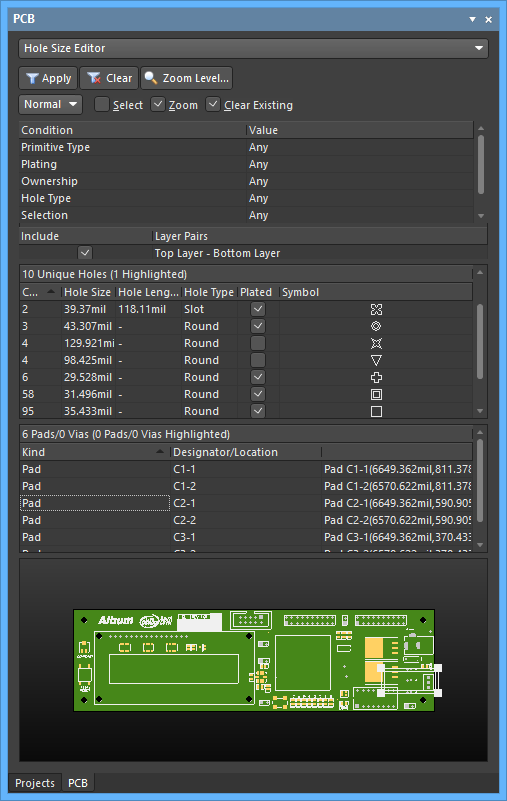

NPTH Slots can be designed in the same manner, and simply designated as NPTH / Mechanical in the CAD software, or they can be designed on the Board Outline Gerber layer. The following images show multiple options for both PTH and NPTH slots, first in a Gerber file view and then a 3D rendering of the resulting board.

Altium Board Slots Game

If you have a question about hole shapes or sizes in your design, please feel free to Contact Us at any time and ask one of our PCB experts. With our flexible PCB Fabrication process at your disposal, never again will you need to fit a square peg in a round hole.

Related Articles:

Search articles:

Altium Board Slot

Slots, milling, contour and rout-outs have to be indicated clearly to be processed correctly in production.

- Do not indicate them in your cupper layers or textprint layers

- Do not indicate them by putting text outside your layout

- Do not indicate them by adding a textfile or any other document together with your datafiles.

But

Altium Board Slots Free

The footprint on the left in this image clearly leaves much more empty space around the component leads, where the image on the right provides a snug fit. This makes the circular hole configuration much more prone to common PCB Assembly defects such as solder joint voiding, since more solder is required to fill the holes.These concerns become more significant as the size of the pins increases, from both design and production perspectives, so large blade-style connectors should definitely use plated slots rather than circular holes. At Bittele, we can still work with circular holes for rectangular pins when the part is relatively small, such as the standard barrel power connector used in this example. That being said, the circular holes do also take up more space on the PCB itself, and using plated slots can often help in size-restricted designs.

For the design of non-circular holes, a few things must be considered, but the process is fairly straightforward overall. It should first be noted that slots can be defined as plated through holes (PTH) or non-plated through-holes (NPTH). PTH slots are most often used in component footprints, and most PCB layout CAD programs provide an option in their footprint editor to define a hole as circular or oval. This will be enough for Bittele's PCB Fabrication team to recognize the hole and use the correct process, but for extra clarity, some clients also indicate slot holes on a fabrication layer of their Gerber files.

NPTH Slots can be designed in the same manner, and simply designated as NPTH / Mechanical in the CAD software, or they can be designed on the Board Outline Gerber layer. The following images show multiple options for both PTH and NPTH slots, first in a Gerber file view and then a 3D rendering of the resulting board.

Altium Board Slots Game

If you have a question about hole shapes or sizes in your design, please feel free to Contact Us at any time and ask one of our PCB experts. With our flexible PCB Fabrication process at your disposal, never again will you need to fit a square peg in a round hole.

Related Articles:

Search articles:

Altium Board Slot

Slots, milling, contour and rout-outs have to be indicated clearly to be processed correctly in production.

- Do not indicate them in your cupper layers or textprint layers

- Do not indicate them by putting text outside your layout

- Do not indicate them by adding a textfile or any other document together with your datafiles.

But

Altium Board Slots App

- Do indicate the slots, milling and routing information into a mechanical layer. A mechanical layer consists of the border of the PCB, together with any other mechanical finishings like extra milling, routing or slots.

- The size of the slots can be indicated in text together with tolerances ( if needed).

- Indicate only one border in your mechanical layer. If you want a round shaped PCB then we expect a round shaped contour,

not a round shaped PCB inside a square box, as this will result in a square shaped PCB…

Examples

- Acceptable contour file indicating slots. The contour layer has to have the same offset as the other copper layers in order to align copper and routing together.

- Properly aligned layers – correct offset to the contour layer

- Not correctly aligned layers – incorrect offset to the contour layer

- Example of acceptable drillmap file indicating slots

- Note that the contour layer is drawn with a normal linewidth (0.2 mm). Do not use the thickness of the router to avoid confusion about the correct dimensions of the PCB. We consider the midpoint of the line as indicator of the correct dimension.

- Slots will be PTH when copper pads are present on top and bottom layer (comparable rule as with normal plated through holes).

- Slots will be NPTH when no copper pads are present on top and bottom layer (comparable with normal non-plated through holes).

- When you need a NPTH slot and copper pads are present, then you will have to indicate this clearly in your design – see example below:

Next >